Jaw plate is the most important accessory to prolong the service life of jaw crusher parts!

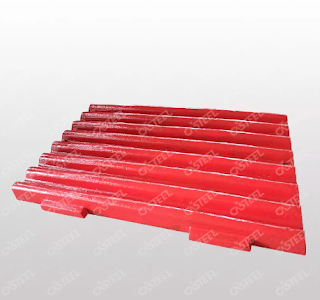

The jaw crusher mainly uses the jaw plate (the jaw plate is composed of the fixed jaw and the movable jaw) to crush the material. In the jaw crusher, the jaw plate needs to withstand huge impact force and friction of the material, which causes the jaw crusher to wear easily. , In order to better protect the jaw plate of the jaw crusher parts, basically a wear-resistant lining plate, also known as the crushing plate, will be installed on the surface of the jaw crusher jaw plate. The surface of the wear-resistant lining plate is basically made into a tooth shape. The angle of the tooth peak of the wear-resistant lining plate is 90 degrees to 120 degrees. The size of the crushing plate is determined by the nature and size of the material to be crushed. However, when crushing large pieces of material, the angle needs to be larger; when crushing small pieces of material, the angle is smaller. The size of the tooth pitch is related to the particle size of the material to be crushe...